1. Use high-quality raw materials

The raw materials from which a composite is produced will play a huge role in the final weight and strength. When it comes to nonwoven raw materials, there is a need for products that have good tensile strength while being thin and light. Synthetic and natural fibers are available and any combination thereof can be used.

Synthetic fibers, such as polyester, polypropylene, polystyrene, and other polymers, are the best choice for strong, lightweight raw materials that can be made into materials that are waterproof, breathable, heat-resistant, flexible, and printable. In order to improve the comfort and breathability of the product, wear-resistant and lightweight raw materials such as cotton can be added.

Regarding the bonding material, polyethylene film will provide the best adhesion while maintaining lightness, softness and flexibility throughout the composite. In addition, polyethylene film can be used in different lamination processes to provide efficient waterproof barrier, high strength and tear resistance.

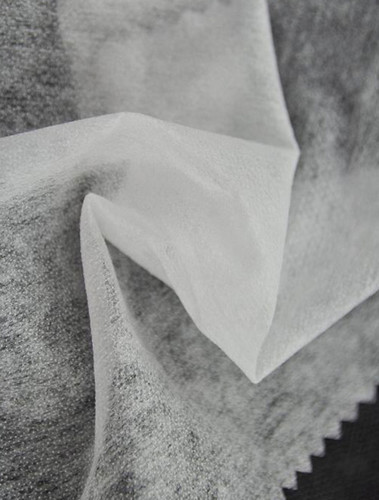

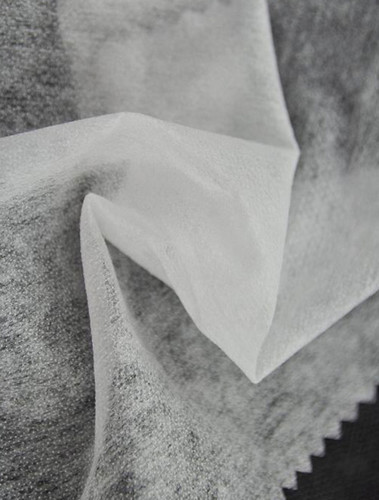

Nylon Nonwoven Interlining Series 8

Nylon Nonwoven Interlining Series 8

Product description:

1:This production adopt advanced double dot coating technique.It has a good performance after dry and water washing with low shrinkage.

2:It widely suits for the materials of silk,cotton,polyester cotton,polyester viscose,chemical fibers,woolen etc.

3:It is suitable for the front parts,collar,sleeve,waistband,placket,pocketing and reinforcement parts of jacket,wind coat,overcoat and suits.

2. Improve tension control

Tension control is one of the most important factors in producing high-quality composite nonwoven products. If the web tension is too high or too low in either direction, it can tear and damage one or more layers in the composite. This is especially true for lightweight materials: the thinner and lighter they are, the more easily damaged nonwoven composites are produced. Poor tension control can also cause wrinkling, areas of incomplete bonding and incompatible ply widths.

A good knowledge of the tensile strength of the raw materials used in composite materials is crucial: for lightweight materials, the tension setting must be absolutely precise, since even the smallest deviations can damage the material.

In this case, it is better to use an intelligent laminating system, such as the A.Celli F-LineⓇ system, which utilizes sensors, cloud technology and software and is able to monitor every step of the process – unwinding, laminating, slitting and coiling.

With a bird's-eye view of the entire process, the system can detect defects and communicate production data in real time, allowing fine-tuning of tension settings without stopping production. This ensures that the tension setting is always optimal, resulting in a high quality end product.

3. Control production speed

The speed of the line must also be controlled throughout the laminating process, as it affects the web tension. Also, especially when coiling the final composite, improper speeds can produce end face shrinkage, wrinkles and air entrapment, resulting in defective rolls.

Ideally, it is desirable to produce as quickly as possible without compromising the quality of the final product. In nonwoven lamination, this means that the speed at which the layers are unwound and fed into the laminating equipment, through the laminating equipment, and at the speed of slitting and winding to form the finished roll, are all critical to obtaining a high-quality product .

As with tension, equipment equipped with sensors and cloud-based services can measure equipment speed and detect defects in materials at various stages of the process. This data can be analyzed and communicated so that necessary adjustments to equipment speed can be made during operation. This capability will ultimately allow you to find the optimum production speed and ensure the integrity of each layer of laminated nonwoven produced and the integrity and quality of the final product.

When these three aspects of the lamination process are precisely controlled, lightweight nonwoven composites that are tight, soft, and comfortable can be produced with minimal risk to the integrity of the individual layers and the final composite.

English

English Español

Español Türk

Türk 简体中文

简体中文