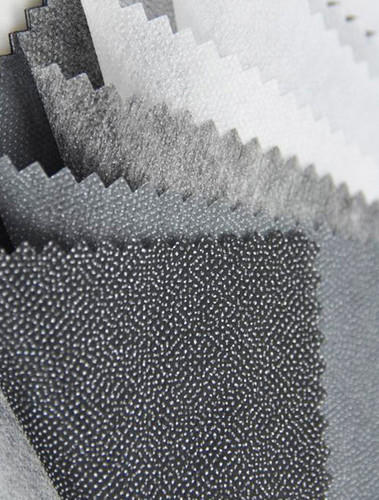

Non-woven fabric is a flat textile product that is formed without spinning and weaving. It consists of short-staple fibers and long-filament fibers that are randomly arranged into a loose web or mat before being bonded together by mechanical, thermal, or chemical processes. This type of textile has several advantages over traditional fabrics: it does not generate lint and is strong and breathable. It is also cheap and easy to form. Polypropylene, polyester, and viscose (rayon) are the most common raw materials for this type of fabric.

It is possible to create non-woven fabrics from various kinds of raw materials, such as polymers, plastics, natural fibers, and other plant raw materials. Moreover, it is possible to combine these fabrics with other materials. The result can be a product with specific functionalities, such as water repellency and flame retardancy.

The production of non-woven fabrics can be divided into two categories: air-laid and wet-laid. The first one is created by using a carding machine, which is used to comb the fibers into a web and align them in the direction of the machine. The other way of creating this product is bypassing the raw fibers into a bin with melted thermoplastic polymer and combining them through mechanical or thermal bonding.

Most non-woven fabrics are disposable, but some can be laundered and reused for a few more uses. For example, polypropylene spunbonds are often used to make reusable shopping bags. Non-woven materials are also incorporated into a variety of consumer durable goods, such as dryer sheets and wet wipes. These products are also used in industrial applications, such as bag liners and shoe bags.

Many kinds of non-woven fabrics are used in the manufacture of automobiles. These include linings for the doors, boot and hoodcase, as well as seat construction. All of these fabrics must be able to meet specific requirements, including high temperature resistance and fogging prevention.

In addition, the use of these textiles in cars must be considered carefully, since they are very likely to have a significant effect on Indoor Environmental Quality (IEQ). Specifically, the IEQ metrics that could be affected by these materials are sound control, glare reduction and humidity regulation.

Generally, non-wovens have a positive impact on IEQ. Whether they are used as upholstery coverings, floor and wall coverings, or as filters of HVAC systems, they reduce the levels of pollutants and volatile organic compounds (VOCs) in the air. They also help to sculpt light and dampen the noise level in a room. However, there are still some issues to consider, such as their ability to collect dust and the need for regular cleaning. It is therefore important to perform more research into the specific effects of different types of non-wovens on the six basic metrics of IEQ. Fortunately, the research has already begun and will continue in the future. The main goal of the research is to determine which characteristics and conditions are most important for ensuring that non-wovens have an optimal influence on IEQ.

English

English Español

Español Türk

Türk 简体中文

简体中文