Shirt Interlining are used to support, reinforce and control areas of a garment. They may be sewn into the fabric or attached with fusing.Depending on the fabric or combination of fabrics used, a fused or non-fused interlining can affect the appearance, durability, mechanical properties and comfort of the finished product. Usually a stain-resistant and/or stain-release coating is preferred.

Shirt Interlining is the technique of attaching fabric between two pieces of collar fabric to create a more attractive collar. Typically, this involves fusing the lining materials together using heat and glue.Fused collars are favored by some makers because of their superior aesthetic. Especially with a tie, they look sharper and flatter.In the past, shirts were made with stiff collars, which were created with liberal applications of starch. Some manufacturers still use a fused lining to achieve this effect, but others prefer the floating linings that give their collars more of a casual look, despite the fact that they are more difficult to make.There are a number of lining options, including both stiff and soft, brushed or non-brushed, with varying weights and shrink-resistance. Some liners are so light that they can be easily removed after several washes, making them perfect for dress shirts.Some bespoke makers combine the two approaches, with floating interlining throughout the collar, and then a fused section just in the ends (shown below). They say it gives the best of both worlds: thicker and stiffer for formal shirts, and soft and comfortable on casual ones.

A float collar is a short section of casing with tool joints on both ends. Float collars are often used for the same reason as float shoes: to reduce the load on the derrick or mast while the big dogs are lowering a new well down into the ground. The best float collars are made of a high-quality stainless steel that stands up to the rigors of saltwater and mucky mucks alike. There are many types of float collars to choose from including the floating collar, the trollomino and the teg-a-twig to name just a few. The teg-a-twig has several advantages over the other float collars but is not suitable for use in high-pressure applications such as sour gas fracking. The teg-a-twig is also more susceptible to snagging on the fracking barge, and can be a costly blunder in a pinch.

Cuffs are a small section of fabric attached at the bottom of a shirt sleeve that prevents the fabric from fraying. They vary in style and often feature a button attached at the end of the sleeve.They can be made from a variety of different fabrics and can also be pattern-matched to the rest of the shirt. They are generally paired with a coordinating collar or yoke to create a well-matched look like on this Randy's Garment Co. upcycled shirt at Lost & Found.Collars are another area where fusing can be used to add more structure. They are usually stiffer than a standard shirt collar because they are glued to the fabric.The fusing process varies depending on the type of interfacing and the fabric being used to make the cuffs. It is a good idea to test the interfacing on a scrap piece of fabric before using it to ensure that it is suitable for the garment and the interfacing does not melt or become too stiff.Fused cuffs can be very easy to sew but they do require a little more attention. First of all, make sure that the cuffs are cut in the correct size. If they do not fit correctly they will not fuse properly. This can be easily remedied by shifting them around until they fit perfectly.

Polyester Nonwoven Interlining Series 0

Polyester Nonwoven Interlining Series 0

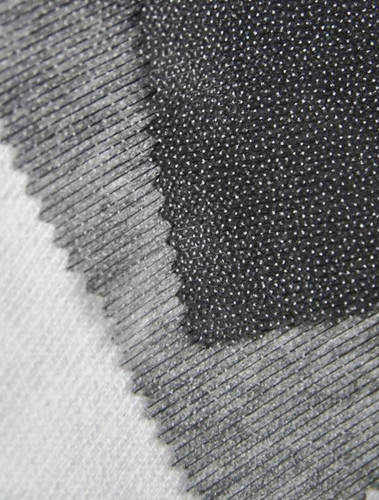

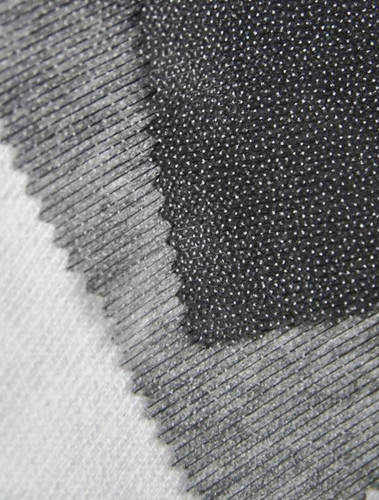

Product description:

1:This production adopt advanced double dot coating technique.It has a good performance after dry and water washing with low shrinkage.

2:It widely suits for the materials of silk,cotton,polyester cotton,polyester viscose,chemical fibers,woolen etc.

3:It is suitable for the front parts,collar,sleeve,waistband,placket,pocketing and reinforcement parts of jacket,wind coat,overcoat and suits.

English

English Español

Español Türk

Türk 简体中文

简体中文