Interlining can be composed of various materials, but commonly it is made up of natural fibers like cotton, wool, or silk, synthetic fibers like polyester or nylon, or a blend of both. Interlining can also be made up of foam, fleece, or other materials that provide additional structure, insulation, or volume to a garment.

Woven interlining is made of fabric that is woven together, while non-woven interlining is made of fibers that are bonded together. Woven interlining tends to be more durable and provide more structure, while non-woven interlining is often more lightweight and flexible.

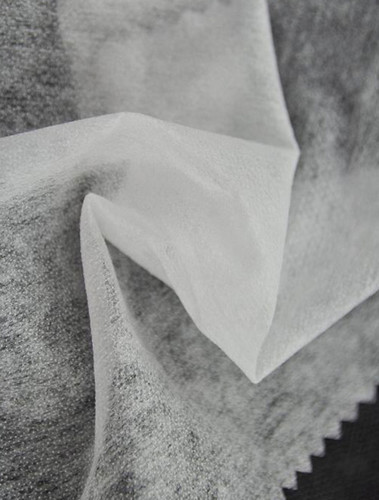

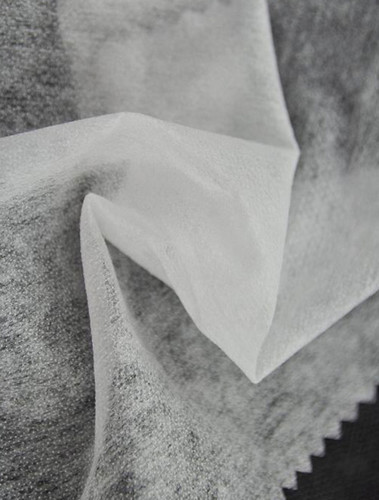

1. Non-woven interlining, to put it bluntly, is a cloth that has not been woven.

The principle of processing technology: the fiber is made of viscose through high temperature and high pressure to form a needle-punched non-woven fabric. Then, a layer of hot melt is applied on the surface of the needle-punched non-woven fabric through a coating machine, and then dried to form the non-woven interlining we commonly use.

Operation method: Put the glued side of the interlining on the fabric, and then heat it with a bonding machine or an electric iron to melt the glue on the interlining, so as to achieve the effect of sticking to the fabric.

Features: low price, soft touch, but not very washable (there will be restrictions on the temperature of the water, usually only resistant to below 70 degrees)

2. There are woven interlinings. The commonly used equipment is key bar looms and water jet looms, and polyester fabrics are made into needle-punched non-woven fabrics through textiles.

The elastic fabric with woven interlining is divided into woven or knitwear. Knitted interlining is also called: knitted fabric, and knitted fabric is generally divided into two types, double-sided elastic knitted interlining, four-sided elastic knitted interlining, and the width of the interlining. Generally, there are two kinds of 110cm and 150cm.

Spinning interlinings now use PA coating. Previously, powdered glue was generally used on the market. It is characterized by a large amount of glue applied and a simple production process. The disadvantage is that due to the large amount of glue applied, it is easy to cause glue penetration. It is now obsolete.

The two-point processing technology without foundation slurry is characterized by easy control of upper clamping force, strong adhesive properties, washable and other treatments. It is now used by most manufacturers. The woven interlining is characterized by strong tensile strength, good ductility, and washability.

Nylon Nonwoven Interlining Series 8

Nylon Nonwoven Interlining Series 8

Product description:

1:This production adopt advanced double dot coating technique.It has a good performance after dry and water washing with low shrinkage.

2:It widely suits for the materials of silk,cotton,polyester cotton,polyester viscose,chemical fibers,woolen etc.

3:It is suitable for the front parts,collar,sleeve,waistband,placket,pocketing and reinforcement parts of jacket,wind coat,overcoat and suits.

English

English Español

Español Türk

Türk 简体中文

简体中文