Industry Knowledge

In the process of improving the air permeability of non-woven fabrics, how does the special needle method balance the relationship between air permeability and strength?

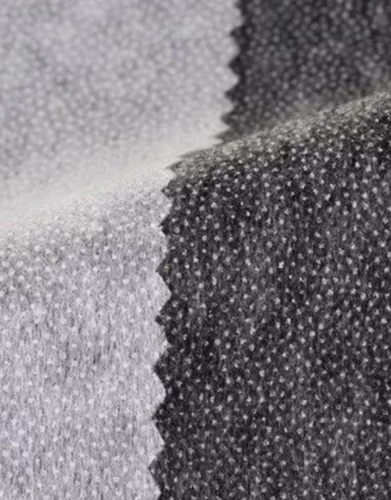

In the process of improving the air permeability of non-woven fabrics, the special needle method cleverly balances the relationship between air permeability and strength through fine process control and design.

1. Optimization of needle punching parameters

The needle punching process in the special needle method is the key to improving the air permeability of non-woven fabrics. By adjusting parameters such as the frequency, depth and needle distance of needle punching, the degree of interweaving of fibers and the microporous structure formed can be accurately controlled. On the one hand, increasing the frequency and depth of needle punching can increase the interweaving points between fibers and improve the strength of non-woven fabrics; on the other hand, appropriate needle punching parameters can retain sufficient microporous structure to ensure that gas molecules can pass smoothly, thereby improving air permeability. Therefore, optimizing needle punching parameters is the key to achieving a balance between air permeability and strength.

2. Selection of fiber materials

The selection of fiber materials also directly affects the air permeability and strength of non-woven fabrics. Some fiber materials with good air permeability, such as certain synthetic fibers or natural fibers, can provide good air permeability while ensuring strength. In addition, fiber modification technology, such as introducing hydrophilic groups or changing the fiber surface morphology, can further improve the air permeability and other properties of non-woven fabrics.

3. Synergy of production process

In addition to the needle punching process and the selection of fiber materials, other production process links such as fiber opening, web forming, and reinforcement also affect the air permeability and strength of non-woven fabrics. By synergizing these process links, the structure and performance of non-woven fabrics can be further optimized. For example, controlling the arrangement and distribution of fibers during web forming and selecting appropriate reinforcement methods and parameters during reinforcement can improve air permeability while achieving strength requirements.

4. Quality control and testing

Implementing strict quality control and testing during the production process is an important means to ensure the balance between air permeability and strength of non-woven fabrics. By regularly testing key indicators such as air permeability and strength of non-woven fabrics, problems in the production process can be discovered and adjusted in a timely manner. At the same time, establishing a sound quality control system can also ensure the consistency and stability of products.

Special needle method successfully balances the relationship between air permeability and strength of nonwoven fabrics by optimizing needle punching parameters, selecting suitable fiber materials, coordinating production process links, and implementing strict quality control and testing.

In addition to needle punching and thermal bonding technology, what other special needle methods or technologies can be used to improve the performance of non-woven fabrics?

In addition to needle punching and thermal bonding technology, there are many other special needle methods or technologies that can be used to improve the performance of non-woven fabrics. These technologies have their own characteristics and can optimize the various properties of non-woven fabrics according to different application requirements.

Hydroentanglement: This is a technology that uses high-pressure fine water flow to spray onto the fiber web to entangle the fibers with each other to enhance the firmness of the fiber web. The non-woven fabric produced by the hydroentanglement method has good hand feel and drape, while maintaining high air permeability and water absorption, and is suitable for medical, sanitation, wiping and other fields.

Wet-laid web technology: This technology places the fiber raw materials in a water medium to open them into single fibers, and then mixes them into a fiber suspension slurry and transports them to the web-forming mechanism, forming a web in a wet state and then reinforcing them into cloth. Wet-laid web technology can produce non-woven fabrics with uniform structure and controllable density, which are suitable for filtration, oil absorption, insulation and other fields.

Spunbond: This is a technology that melts and extrude polymers to form continuous filaments, then lays them into a fiber web and reinforces them into cloth by self-bonding, thermal bonding, etc. The non-woven fabrics produced by the spunbond method have high strength and wear resistance, and are suitable for packaging, agricultural covering, building waterproofing and other fields.

Meltblown: The meltblown method feeds and melts the polymer to form fibers, which are then cooled, formed into a web and reinforced into cloth. This technology can produce ultra-fine fiber non-woven fabrics with excellent filtration performance and air permeability, and is widely used in air filtration, liquid filtration and other fields.

Stitchbond: The combination and reinforcement of materials such as fiber webs using warp knitting coil structures can produce non-woven fabrics with high strength and good structural stability, which are suitable for occasions that need to withstand greater tension and stress.

In addition, some emerging technologies such as nanotechnology and plasma surface treatment technology have also been applied to the production of non-woven fabrics to further improve their performance. These technologies give non-woven fabrics new functional properties such as antibacterial, antifouling, and antistatic by changing the surface properties or structure of the fibers.

There are many different production technologies for non-woven fabrics, and each technology has its unique application advantages and fields. With the continuous development of science and technology, more new non-woven fabric production technologies will emerge in the future to meet the increasingly diversified needs of the market.

English

English Español

Español Türk

Türk 简体中文

简体中文